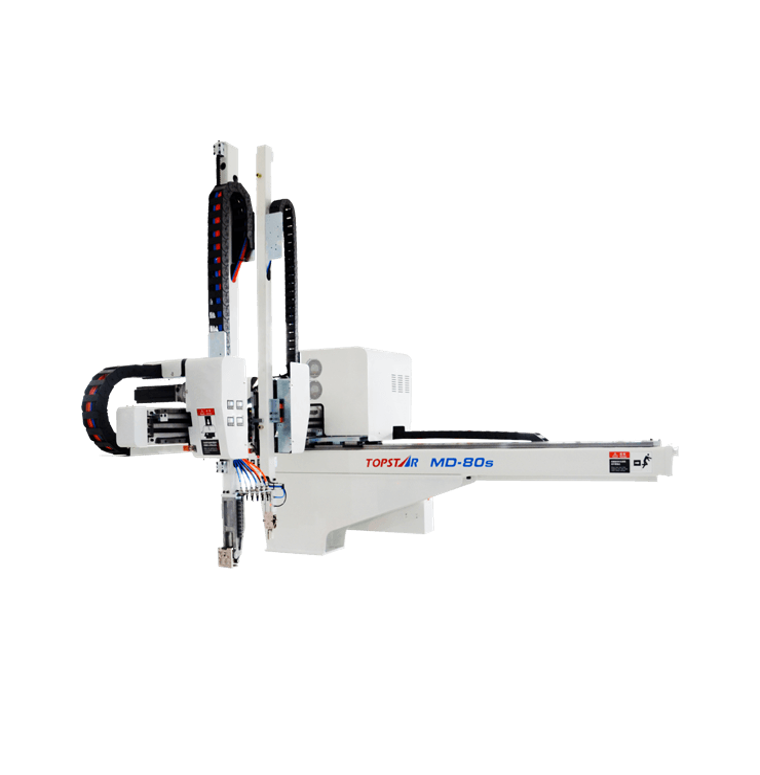

MBW Series AC Servo Injection Robots

The Three/Five Axis AC Servo Driven Robots are well-suited for horizontal injection molding machines ranging from 75T to 1300T. These robots are specifically designed for the removal of finished products and sprues, catering to applications with elevated demands for both appearance and precision

The fifth generation of "five-in-one servo-driven manipulator" technology

Features of the manipulator: precise, energy-saving, and intelligent five-in-one servo

-

“Five-in-one servo drive” enables one servo driver to directly control five servo motors, each CPU chip controls two axes, and the maximum power of each axis is 750W. This provides a powerful power for the robot. Combined with the multi-axis common busbar design, the energy efficiency is improved by 20%.

Support multi-track application

-

The self-developed open system can bring great convenience to the operator. Only by using the hand controller to modify the program, servo parameters and mechanical parameters or modify the application program according to the needs, can it realize traction, hook, slip, oblique line and even irregular removal paths, and can also realize special actions such as arrangement, stacking, counting, sampling, etc.

The concept of integrated process from communication to integration

-

The manipulator can support the host call signal, and realize integrated operation, and the control system automatically optimizes the removal process link to improve the injection molding efficiency of the production line. It solves the problems of ejection position deviation and uncoordinated suction time leading to removal failure and equipment alarm shutdown.

-

It realizes synchronous linkage with the mold opening process, and the early arrival and “automatic follow-up” functions reduce the number of abnormal alarms and equipment maintenance, further improving production efficiency. The production efficiency of each injection unit is increased by 5%.

Training for Installation and Operation Correctly

We have a comprehensive after-sales training system. To address potential issues and ensure optimal operation, we provide you with the necessary training resources for installing and operating the packaging machine.

-

Instructions for Use – Installation Steps and Operating Precautions

-

Video demonstration of installation and debugging

-

On-site training – additional service fee required